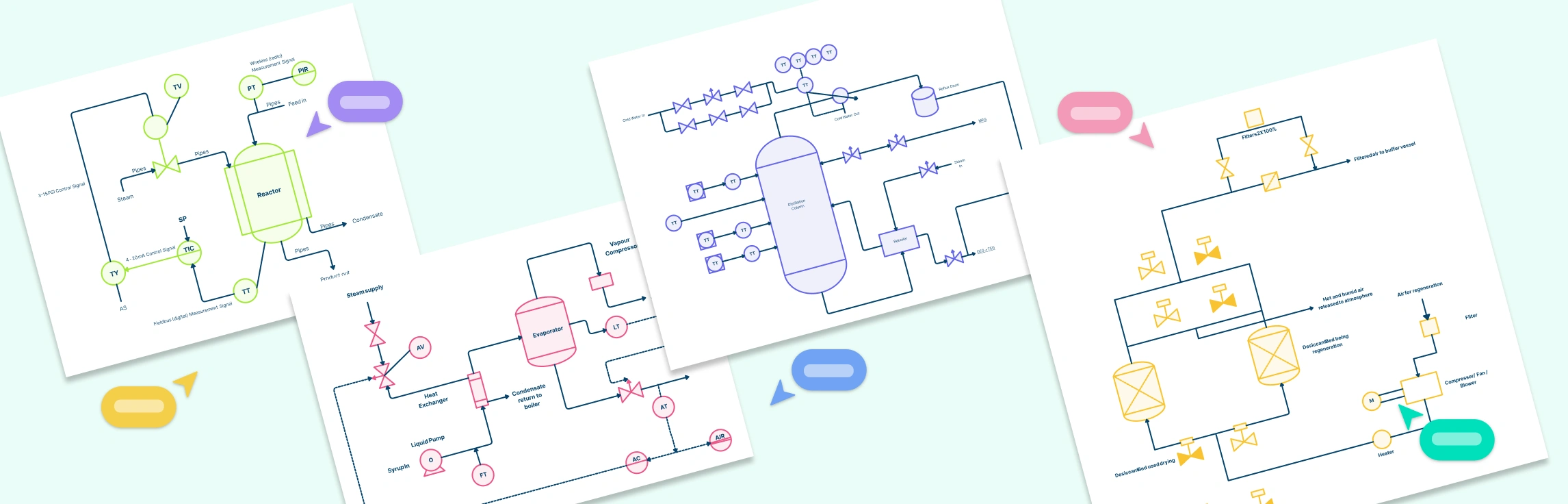

Piping and Instrumentation Diagrams (P&IDs) are essential tools in process engineering, helping professionals visualize systems, monitor controls, and optimize workflows. Whether you’re designing a chemical reactor, managing a heat exchanger, or planning large-scale production processes, having clear and accurate P&ID examples can save time and reduce errors.

In this guide, we’ve compiled 10 practical P&ID examples, complete with editable templates, to help engineers, students, and designers quickly understand process flows, instrumentation layouts, and piping connections. Each example includes a ready-to-use template, making it easier to implement in real-world projects or training sessions.

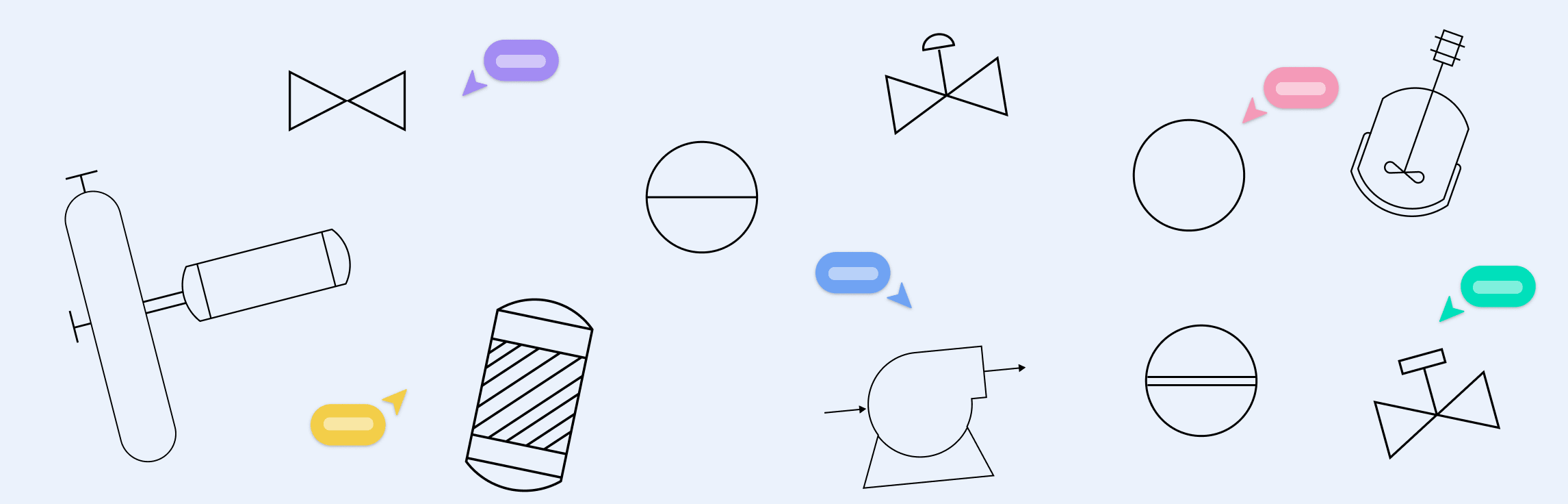

What Is a Piping and Instrumentation Diagram?

A Piping and Instrumentation Diagram (P&ID) visually represents a process flow, showing the piping, equipment, and instrumentation used in a system. These diagrams are essential in process engineering for planning, design, and troubleshooting. For a deeper dive, check out our full guide on piping and instrumentation diagrams.

10 Free P&ID Templates

1. Piping and Instrumentation Diagram

A versatile P&ID template suitable for a wide range of processes, this diagram shows piping layouts, control loops, and instrumentation for general process engineering needs. It’s an excellent starting point for custom designs or training purposes.

2. Heat Exchanger P&ID Example

The heat exchanger P&ID example demonstrates how fluids transfer heat efficiently between systems. It includes pumps, valves, and temperature monitoring points, making it ideal for thermal management. This editable template simplifies the design of heat exchange processes in any plant setup.

3. Water Boiling Process P&ID Template

This template showcases the water boiling process, highlighting the flow of water, steam generation, and control mechanisms. Key instrumentation symbols, including pressure gauges and level sensors, are clearly represented, making it perfect for training or practical implementation.

4. Production P&ID Template

Designed for large-scale industrial processes, this production P&ID template maps complex systems, including pipelines, reactors, and storage units. It helps engineers plan, monitor, and optimize production workflows efficiently.

5. Block Flow Diagram Example for Production of Benzene

This block flow diagram template offers a simplified overview of benzene production, showing major process units and material flows without detailed instrumentation. It’s ideal for high-level planning and comparison with detailed P&ID layouts.

6. Block Flow Diagram Example for Acrylic Acid

This template focuses on the acrylic acid production process, providing a clear and concise view of the main process stages. It’s perfect for presentations or initial design planning where simplicity and clarity are key.

7. Block Flow Diagram Example for Recovery of Gas and Oil

Illustrating the recovery of gas and oil, this block flow diagram highlights core units, separation stages, and material flows. It’s a practical engineering template for industrial use, helping teams understand and optimize recovery processes.

8. Block Flow Diagram Example for Butadiene Extraction

This example outlines the butadiene extraction process, emphasizing major process steps and critical instrumentation points. It serves as a useful reference for process engineers designing or reviewing extraction workflows.

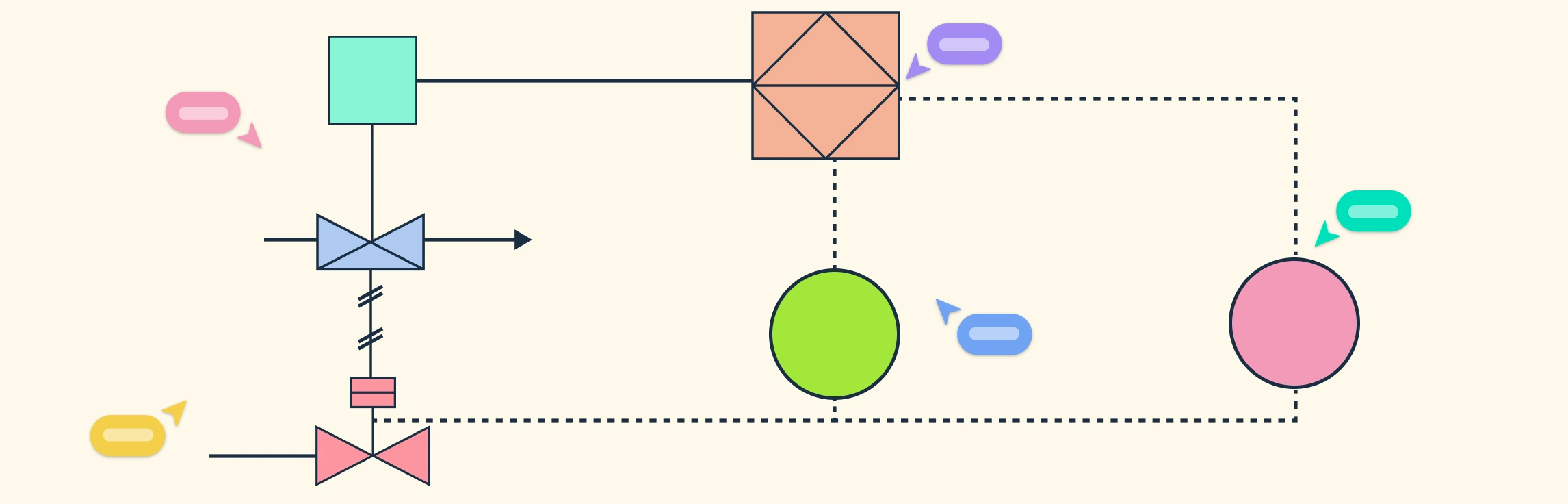

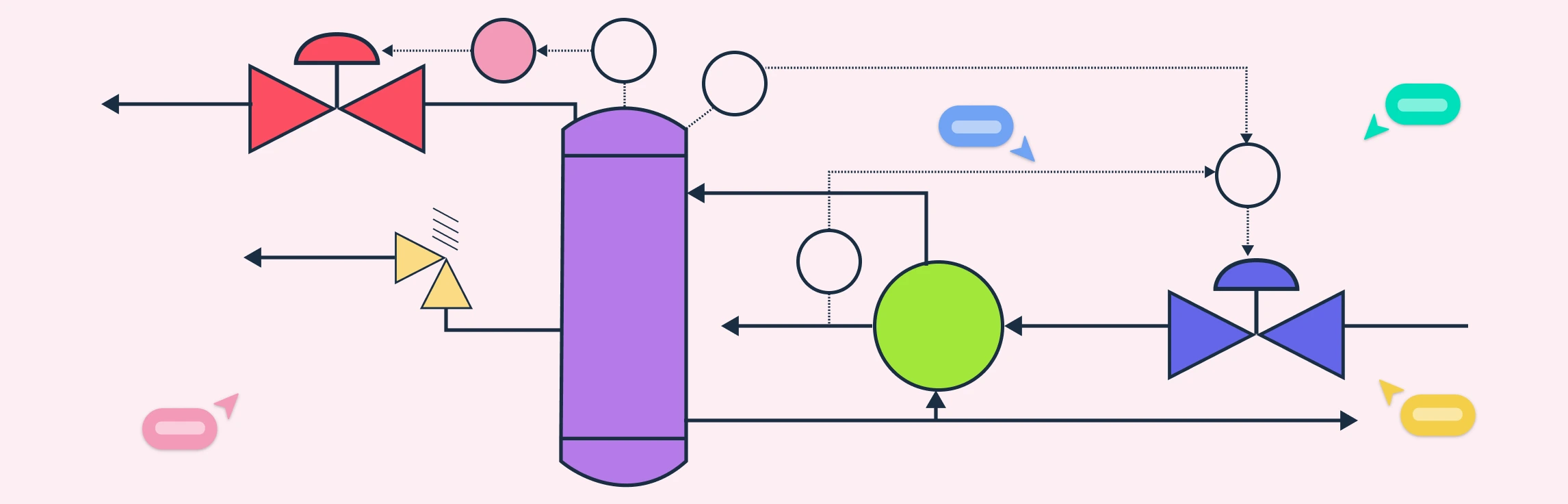

9. Pressurized Vessel P&ID Diagram

This pressurized vessel P&ID diagram demonstrates pressure control, safety valves, and instrumentation used to monitor and regulate high-pressure systems. It’s essential for designing safe operations in chemical and industrial applications.

10. Chemical Reactor P&ID Example

This chemical reactor P&ID example illustrates the flow of reactants, catalysts, and products within a reactor system. It highlights critical instrumentation, such as temperature and pressure sensors, and control valves to ensure safe and efficient operation. Use this process engineering template to quickly design or review chemical processes.

Why P&ID Examples Are Useful

Using P&ID examples offers multiple advantages for engineers, students, and process designers. Here’s how they can make your workflow more efficient and reliable:

Accelerate Learning

Clear visual references help users understand complex chemical processes and production workflows quickly.

Standardize Designs

Examples promote consistency across projects, ensuring uniformity in system layouts and design symbols.

Reduce Errors

Pre-built diagrams minimize the chances of miscommunication or design flaws during implementation.

Improve Design Accuracy

For systems like heat exchangers or pressurized vessels, ready-made templates make it easier to create detailed, precise piping and instrumentation diagrams.

Save Time and Effort

Instead of building P&IDs from scratch, templates allow faster customization and integration into existing projects.

Enhance Process Understanding

Studying real-world P&ID examples helps teams visualize process flows, control loops, and instrumentation placement effectively.

These P&ID examples and templates make the designing process systems easier, faster, and more accurate. By using ready-made diagrams for chemical processes, production workflows, and heat exchangers, engineers and designers can streamline planning, reduce errors, and save valuable time. Download the templates today and start implementing these practical examples to enhance your piping and instrumentation diagrams with confidence.